Epoxy flooring offers a durable, sleek solution for various settings, but installing it can be a challenge if you’re unfamiliar with the common pitfalls.

In this article, we explore the most frequent epoxy flooring mistakes that homeowners and businesses make, and provide actionable advice to help you avoid them.

Whether you’re planning epoxy flooring for a garage, driveway, or a commercial space in the Sunshine Coast, this guide will ensure your project is set up for success.

Table of Contents

- Introduction to Epoxy Flooring Mistakes

- Poor Surface Preparation: A Critical First Step

- Misjudging Environmental Conditions

- Incorrect Mixing Ratios and Techniques

- Applying Layers Too Thick or Too Thin

- Ignoring Expansion Joints

- Rushing the Curing Process

1. Introduction to Epoxy Flooring Mistakes

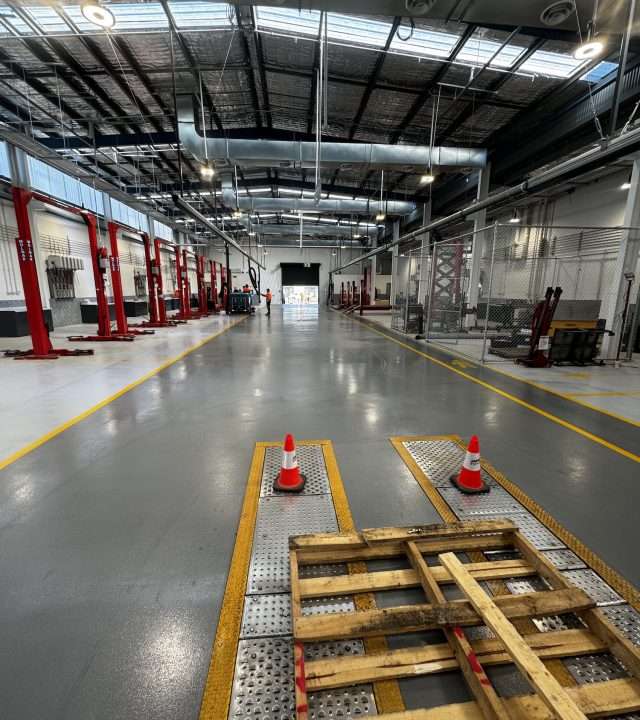

Epoxy flooring is a popular choice for both residential and commercial applications due to its toughness, chemical resistance, and aesthetic appeal. However, improper installation can quickly turn a great investment into a costly headache.

Understanding common epoxy flooring mistakes, like poor surface preparation and incorrect mixing ratios, is essential to achieving a smooth, long-lasting finish. Here, we’ll walk you through the most critical errors to avoid.

2. Poor Surface Preparation: A Critical First Step

One of the biggest epoxy flooring mistakes is failing to properly prepare the surface. Any existing dust, dirt, grease, or moisture can prevent the epoxy from bonding effectively to the concrete. Even a small contamination can lead to peeling, blistering, or an uneven finish.

We always start by cleaning the concrete thoroughly, often with mechanical grinding or shot blasting, ensuring a pristine surface. After cleaning, we repair any cracks or imperfections. Inadequate preparation can cause the epoxy to lift, crack, or fail prematurely, so never underestimate this step.

3. Misjudging Environmental Conditions

Another common epoxy flooring mistakes are overlooking the impact of environmental factors like temperature and humidity. Epoxy reacts to these conditions, and applying it under improper circumstances can lead to bubbling or an inconsistent finish.

For the Sunshine Coast climate, we always monitor both temperature and humidity carefully. Epoxy floors should be installed in conditions that are not too hot or too cold, with the ideal temperature range being between 15°C and 30°C. Humidity levels above 85% can cause issues like clouding or improper curing, so timing is key.

4. Incorrect Mixing Ratios and Techniques

When it comes to mixing epoxy, precision is everything. Epoxy flooring mistakes – Incorrect ratios between resin and hardener can lead to epoxy that doesn’t cure properly, resulting in a soft or tacky surface. Furthermore, improper mixing techniques—such as mixing too quickly or too slowly—can introduce bubbles or result in uneven curing.

We ensure that the mixing is done according to the manufacturer’s exact instructions, often using mechanical mixers to guarantee consistency. Mixing should be done slowly but thoroughly to avoid air bubbles that can ruin the finish.

5. Applying Layers Too Thick or Too Thin

The thickness of each epoxy layer is crucial for durability and appearance. Applying the product too thickly can cause it to crack or bubble, while layers that are too thin may wear down quickly, especially in high traffic areas.

Our approach is to apply the correct number of layers based on the space’s usage. For instance, a residential garage may require fewer layers than a busy commercial setting. We use professional equipment to measure and apply the epoxy evenly, ensuring a durable, long lasting finish.

6. Ignoring Expansion Joints

Concrete naturally expands and contracts with temperature changes. Failing to account for this movement by ignoring expansion joints can result in cracking, as the epoxy will not have the flexibility it needs.

We incorporate expansion joints into every epoxy flooring project to accommodate these shifts. This helps prevent unsightly cracks and prolongs the lifespan of the floor, especially in larger spaces like commercial warehouses or outdoor areas like driveways.

7. Rushing the Curing Process

Patience is key when installing epoxy flooring. Many DIY installers make the mistake of rushing the curing process, either by walking on the floor too soon or by applying additional coats before the previous layer has fully set.

We understand that epoxy requires time to cure properly. Rushing this stage can result in a weak bond, which can cause peeling or uneven surfaces. We allow each layer to dry and cure fully before proceeding with the next step, ensuring a professional grade finish.

Why Choose Our Epoxy Flooring Services

At our company, we specialise in providing high quality epoxy flooring solutions across the Sunshine Coast. Here’s why you should choose us to avoid epoxy flooring mistakes:

- Expert Preparation: We take the time to meticulously prepare every surface, ensuring long lasting results.

- Precise Installation: With attention to detail in mixing and applying epoxy, we guarantee a flawless finish.

- Climate Control: We work around environmental conditions, so your floor cures correctly every time.

- Durable Results: Whether for a garage, driveway, or commercial space, our floors are built to last.

- Customer Care: We offer free quotes and tailor each project to your specific needs.

Contact us today to discuss your next project or to request a free quote!

FAQs

- What is the most common mistake in epoxy flooring installation?

The most common epoxy flooring mistakes are poor surface preparation, which prevents the epoxy from bonding properly to the concrete. This leads to issues like peeling and bubbling. - Can epoxy flooring be installed in high humidity areas?

Yes, but special care must be taken to monitor humidity levels, which can affect curing. We adjust installation schedules to ensure the epoxy sets correctly. - How long does it take for epoxy flooring to cure?

Typically, it takes 24-72 hours for epoxy to fully cure, depending on the environmental conditions and the specific product used. - Can I apply epoxy flooring myself?

While DIY epoxy flooring is possible, it requires careful attention to preparation, mixing, and environmental conditions to avoid common mistakes.

- Is epoxy flooring suitable for outdoor areas like driveways?Yes, epoxy flooring can be used for driveways and other outdoor areas. We use specialised products designed to withstand weather exposure.

- How thick should epoxy flooring be?

The thickness depends on the application, with residential floors typically being thinner than commercial or industrial installations. We adjust the thickness to match usage needs. - How do you fix epoxy flooring mistakes?

Depending on the epoxy flooring mistakes, fixes may involve sanding, re-coating, or in severe cases, removing the existing epoxy and starting over. Prevention is always the best approach.